Chemical Desiccant Molecular Sieve Zeolite Manufacturer – 1.6~2.5mm Zeolite molecular sieve 3a 4a 5a structure, chemistry, and use – Xinzheng Cheng

Chemical Desiccant Molecular Sieve Zeolite Manufacturer – 1.6~2.5mm Zeolite molecular sieve 3a 4a 5a structure, chemistry, and use – Xinzheng Cheng Detail:

Adsorption performance

The adsorption of zeolite molecular sieve is a physical change process. The main reason for adsorption is a kind of “surface force” produced by molecular gravity acting on the solid surface. When the fluid flows through, some molecules in the fluid collide with the surface of the adsorbent due to irregular motion, causing molecular concentration on the surface. Reduce the number of such molecules in the fluid to achieve the purpose of separation and removal. Since there is no chemical change in adsorption, as long as we try to drive away the molecules concentrated on the surface, the zeolite molecular sieve will have adsorption capacity again. This process is the reverse process of adsorption, called analysis or regeneration. Since the zeolite molecular sieve has a uniform pore size, only when the molecular dynamics diameter is smaller than the zeolite molecular sieve can it easily enter the inside of the crystal cavity and be adsorbed. Therefore, the zeolite molecular sieve is like a sieve for gas and liquid molecules, and it is determined whether to be adsorbed or not according to the size of the molecule. . Since the zeolite molecular sieve has a strong polarity in the crystalline cavity, it can have a strong effect on the surface of the zeolite molecular sieve with molecules containing polar groups, or by inducing the polarization of the polarizable molecules to produce strong adsorption. This kind of polar or easily polarized molecules is easy to be adsorbed by polar zeolite molecular sieve, which reflects another adsorption selectivity of zeolite molecular sieve.

Ion exchange performance

Generally speaking, ion exchange refers to the exchange of compensation cations outside the framework of the zeolite molecular sieve. The compensation ions outside the framework of the zeolite molecular sieve are generally protons and alkali metals or alkaline earth metals, which are easily ion-exchanged into various valence metal ion-type zeolite molecular sieves in the aqueous solution of metal salts. Ions are easier to migrate under certain conditions, such as aqueous solutions or higher temperatures.

In aqueous solution, due to the different ion selectivity of zeolite molecular sieves, different ion exchange properties can be exhibited. The hydrothermal ion exchange reaction between metal cations and zeolite molecular sieves is a free diffusion process. The diffusion rate restricts the exchange reaction rate.

Catalytic performance

Zeolite molecular sieves have a unique regular crystal structure, each of which has a pore structure of a certain size and shape, and has a large specific surface area. Most zeolite molecular sieves have strong acid centers on the surface, and there is a strong Coulomb field in the crystal pores for polarization. These characteristics make it an excellent catalyst. Heterogeneous catalytic reactions are carried out on solid catalysts, and the catalytic activity is related to the size of the crystal pores of the catalyst. When a zeolite molecular sieve is used as a catalyst or a catalyst carrier, the progress of the catalytic reaction is controlled by the pore size of the zeolite molecular sieve. The size and shape of the crystal pores and pores can play a selective role in the catalytic reaction. Under general reaction conditions, zeolite molecular sieves play a leading role in the reaction direction and exhibit shape-selective catalytic performance. This performance makes zeolite molecular sieves a new catalytic material with strong vitality.

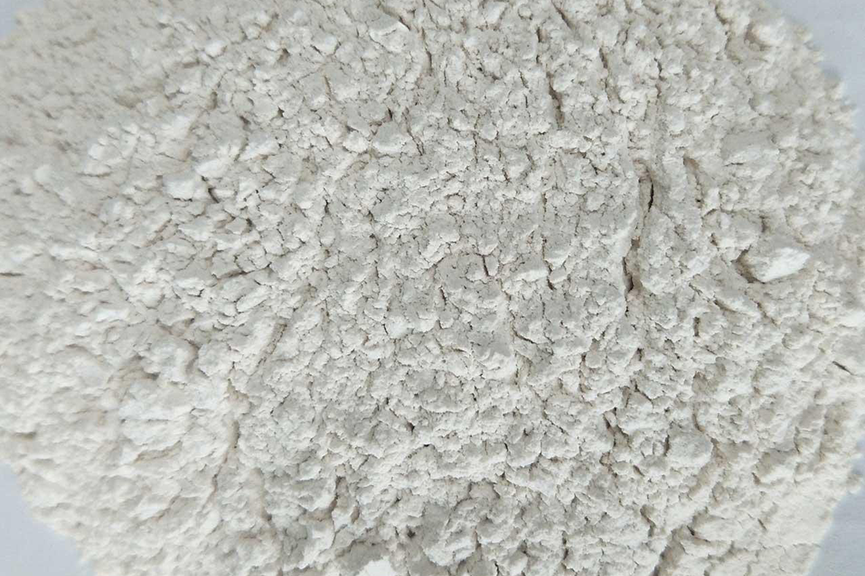

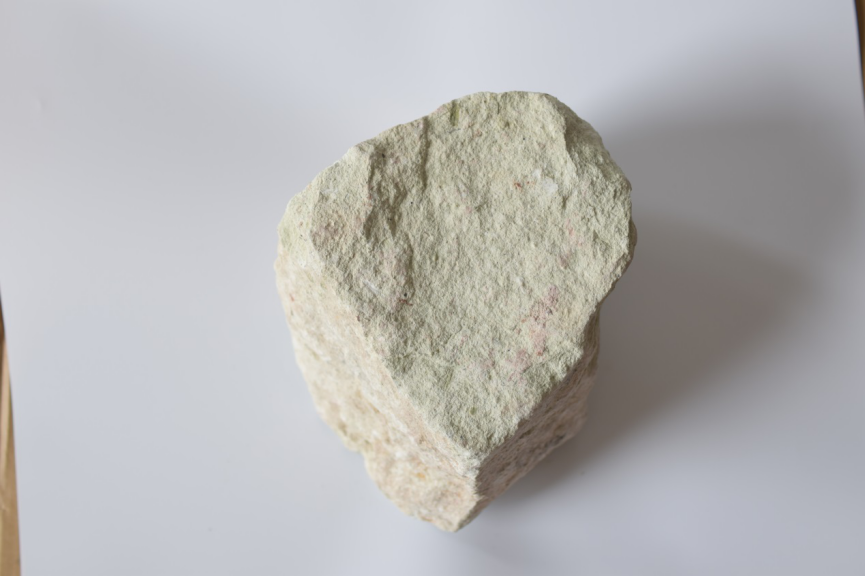

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Chemical Desiccant Molecular Sieve Zeolite Manufacturer – 1.6~2.5mm Zeolite molecular sieve 3a 4a 5a structure, chemistry, and use – Xinzheng Cheng , The product will supply to all over the world, such as: Mauritius, Guyana, Algeria, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!