-

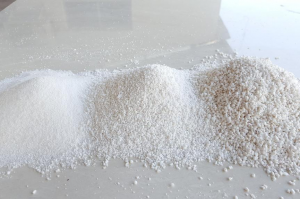

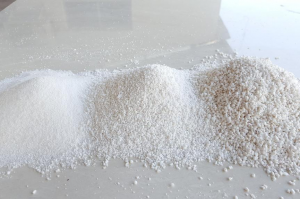

bulk Closed Cell Perlite For Thermal Insulation Mortar

closed cell perlite is made of perlite ore with a certain particle size in a vertical electric furnace cascade heating method, and then expands uniformly from the inside to the outside after reaching a certain temperature. The surface of the expanded particles is vitrified at an instant high temperature, and the continuous vitrification is formed after cooling. The surface of the particles, and the inside maintains a complete porous, hollow structure. The unique production method determines that the product maintains the purity of the natural inorganic chemical composition of perlite. The structural feature of the product is that the surface of the particles is micro-pores and continuous vitrified luster, and the content shows a few or dozens of tiny spherical accumulations, and the color is white. The bulk density of the product is 110~350kg/cubic; the particle size is 5~1500μm.

-

high temperature expanded perlite for sale

Expanded perlite is a kind of white granular material with honeycomb structure inside, which is made by preheating perlite ore and then roasting and expanding at instantaneous high temperature. The working principle of Expanded perlite is: perlite ore is crushed to form ore sand of a certain size, after preheating roasting, rapid heating (above 1000 ℃), the water in the ore evaporates and expands inside the softened vitreous ore to form a porous structure and volume expansion 10-30 times the non-metallic mineral products. Perlite is divided into three forms according to its expansion technology and use: open cell, closed cell, and balloon.

-

buy Horticultural Perlite bulk for commercial growers

Horticultural perlite is a kind of white granular material with honeycomb structure inside after preheating perlite ore after instant high temperature roasting and expansion. Its principle is: perlite ore is crushed to form ore sand of a certain size, after preheat Thermal roasting, rapid heating (above 1000°C), the moisture in the ore evaporates, and expands inside the softened vitreous ore to form a porous structure, a non-metallic mineral product with a volume expansion of 10-30 times.

-

best pure Hydrophobic Perlite Used in External Insulation

Hydrophobic perlite is hydrophobically modified on the basis of expanded perlite to achieve excellent waterproof effect. Its thermal conductivity is low, generally around 0.045W/m.k, and the lowest is 0.041W/m.k. The outer surface has a sealed glass bulb, so thatHydrophobic perlite has high compressive strength and is not easy to be destroyed, which can greatly reduce the damage rate during use and effectively maintain the practical insulation effect. At the same time, the water absorption of the material is reduced, and the amount of water added to the proportion is reduced, so that the overall drying time of the material is significantly shortened, which helps to improve the construction efficiency.

-

industrial perlite ore for foundry manufacturers

Perlite is a kind of volcanic eruption acid lava, vitreous rock formed by rapid cooling. Perlite ore is a raw ore product made by crushing and screening perlite ore. Various specifications of perlite products can be made according to the needs of customers.

-

Expanded perlite powder manufacturers in China

Perlite powder is a kind of ultrafine white powdered perlite separated above the silo during the expansion process of expanded perlite.

-

best price perlite filter aid powder suppliers in China

Perlite filter aid is a powdered chemical product with a certain particle size obtained by selective expansion of selected small-sized ore sands, heated by purified gas, in a vertical shaft kiln, expansion, and grinding and purification.

-

high quality daily Brilliant expanded perlite for sale

Brilliant expanded perlite is a kind of porous structure, white, granular loose material made from acidic volcanic vitreous lava through crushing, preheating, roasting and expansion. It has small capacity, low thermal conductivity, good chemical stability, non-combustible, non-flammable and non-flammable. Poisonous, odorless, sound-absorbing and other characteristics.

-

Hot selling Expanded and vitrified ball for sale

Expanded and vitrified ball are due to the vitrification of the surface to form a certain particle strength, the physical and chemical properties are very stable, the aging and weather resistance is strong, and they have excellent heat insulation, fire protection and sound absorption properties. They are suitable for light filling aggregates and heat insulation and fire protection in many fields. ﹑Sound-absorbing and thermal insulation materials. In the building materials industry, using Expanded and vitrified ball as lightweight aggregates can improve the fluidity and self-resistance of the mortar, reduce the shrinkage of material properties, improve the overall performance of the product, and reduce the overall production cost.

-

HGM Hollow Glass Microspheres thermal insulation manufacturers

The hollow glass microspheres are off-white in appearance, which is a loose powder material with good fluidity. The characteristics are: sound insulation, flame retardation, good electrical insulation, low density, low oil absorption, and high strength. It is widely used in printing inks, adhesives, engineering plastics, modified rubber, and electrical insulation parts. Because of its stable performance, good weather resistance, and low price, it has been widely used.

The main components of the hollow glass microspheres are silicon dioxide-SiO2 and aluminum oxide-Al2O3 after being fired and sorted at a high temperature of 1400°C. The diameter of hollow glass microspheres is between 5 and 1000 microns.

-

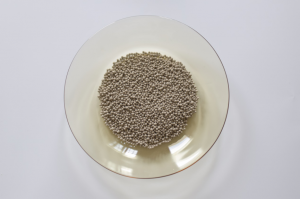

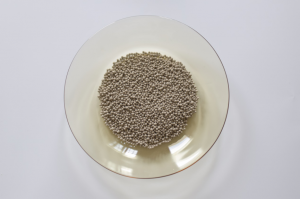

Powder metallurgy hollow fly ash cenosphere particles supplies

fly ash cenosphere is a kind of fly ash hollow ball that can float on the water surface. fly ash cenosphere is off-white, with thin and hollow walls, very light weight, 160-400 kg/m3, particle size of about 0.1-0.5 mm, and the surface is closed and smooth. Low thermal conductivity, refractoriness ≥1610℃, it is an excellent thermal insulation refractory material, widely used in the production of lightweight castables and oil drilling. The chemical composition of fly ash cenosphere is mainly silica and aluminum oxide. It has many characteristics such as fine particles, hollow, light weight, high strength, wear resistance, high temperature resistance, thermal insulation, insulation and flame retardant.

-

paint additive Ceramic Powder for sale

Ceramic powder is a light non-metallic multifunctional material. The main components are SiO2 and Al2O3. Ceramic powder has good dispersibility, high hiding power, high whiteness, good suspension, good chemical stability, good plasticity, high heat-resistant temperature, and high density. Small, low loss on ignition, good light scattering and good insulation. It can improve the adsorption, weather resistance, durability, scrubbing resistance, corrosion resistance and high temperature resistance of the paint, improve the mechanical properties of the paint film, increase transparency, and improve the fire resistance. It can be used for anticorrosion, fire resistance, high temperature resistance, powder, architectural coatings and Various industrial and civil coatings are especially suitable for high-gloss semi-gloss coatings and other solvents. They can replace the amount of titanium dioxide, eliminate the photo-flocculation phenomenon caused by the use of titanium dioxide, prevent the yellowing of the paint, and reduce the production cost of the enterprise. Ceramic powder is known as “new material in the space age