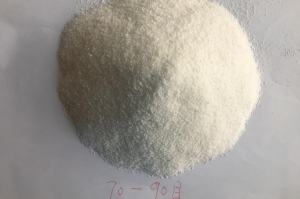

high quality daily Brilliant expanded perlite for sale

Quick details of Brilliant expanded perlite

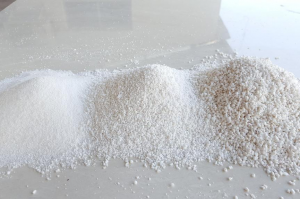

Brilliant expanded perlite is a kind of porous structure, white, granular loose material made from acidic volcanic vitreous lava through crushing, preheating, roasting and expansion. It has small capacity, low thermal conductivity, good chemical stability, non-combustible, non-flammable and non-flammable. Poisonous, odorless, sound-absorbing and other characteristics.

Introduction of Brilliant expanded perlite

Brilliant expanded perlite (expanded perlite for ultra-low temperature and super-strength engineering) is a product obtained by selecting small particles of fine powder and ore in a vertical shaft kiln with natural gas as a heat source, and heating and expanding. The enhanced product is sprayed with silicone on the surface of the expanded perlite , Forming a hydrophobic structure. The color, bulk density and specifications of the product are similar to ordinary expanded perlite. This product is mainly used for the construction of large-scale ultra-low temperature thermal engineering insulation layer, such as oxygen production air separation unit, natural gas, liquid hydrogen, liquid nitrogen, liquid oxygen refrigerated transport vehicles and ships. This product has good ultra-low temperature insulation performance.

Technical indicators of Brilliant expanded perlite

| No. | Item | Unit | Performance | |||

| SP-50 type | SP-60 type | |||||

| 1 | Bulk density | Kg/m3 | 35~50 | 45~60 | ||

| 2 | Tap density | Kg/m3 | 45~60 | 55~70 | ||

| 3 | Particle size (wt% ratio) | 1.2mm flow rate | % | 1.2mm—0.154mm ≥90% | 1.2mm—0.154mm ≥90% | |

| 0.154mm flow rate | % | 0.154mm max 10% | 0.154mm max 10% | |||

| 4 | Mass moisture content (wt% ratio) | % | ≤0.5 | ≤0.5~1 | ||

| 5 | Repose angle (when stacking height is 100mm) | 0 | 33~37 | |||

| 6 | Increase in density during filling | Manual | % | ≤25 | ||

| Wind | % | ≤35 | ||||

| 7 | The thermal conductivity is (average value of atmospheric temperature at 77K---310K) | w/(m.k) | 0.022~0.025 | 0.024~0.026 | ||

| 8 | Operating temperature | ℃ | -200~800 | |||

| Note: The bulk density in the table, the tap density is the maximum value. | ||||||