Zirconia Powder Supplier – bulk Closed Cell Perlite For Thermal Insulation Mortar – Xinzheng Cheng

Zirconia Powder Supplier – bulk Closed Cell Perlite For Thermal Insulation Mortar – Xinzheng Cheng Detail:

Introduction of closed cell perlite

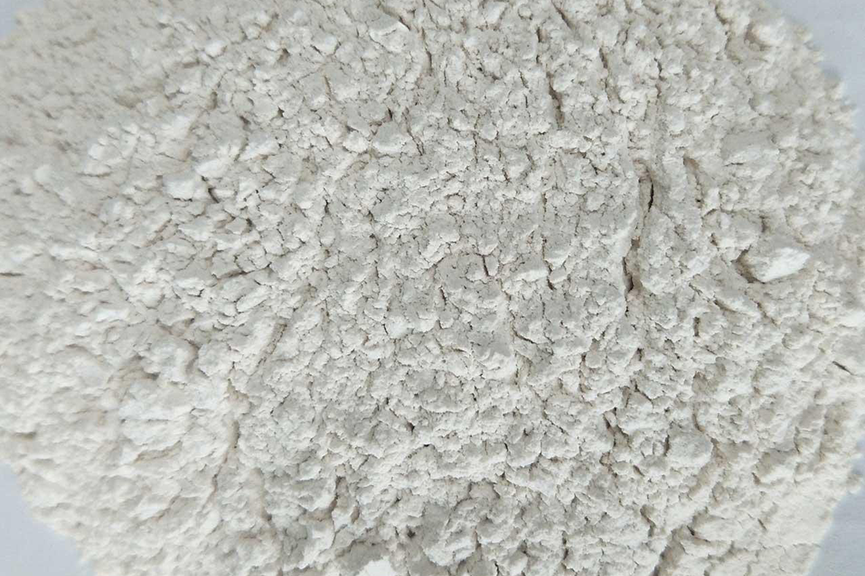

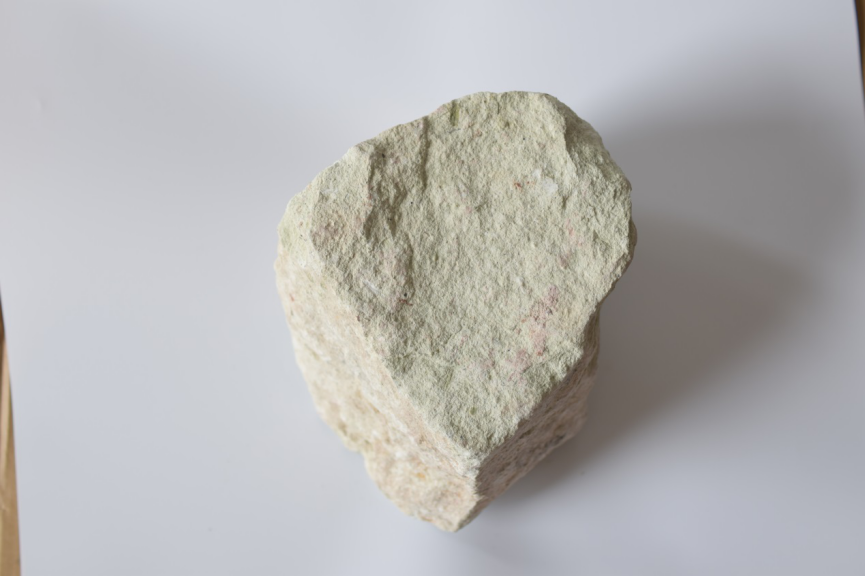

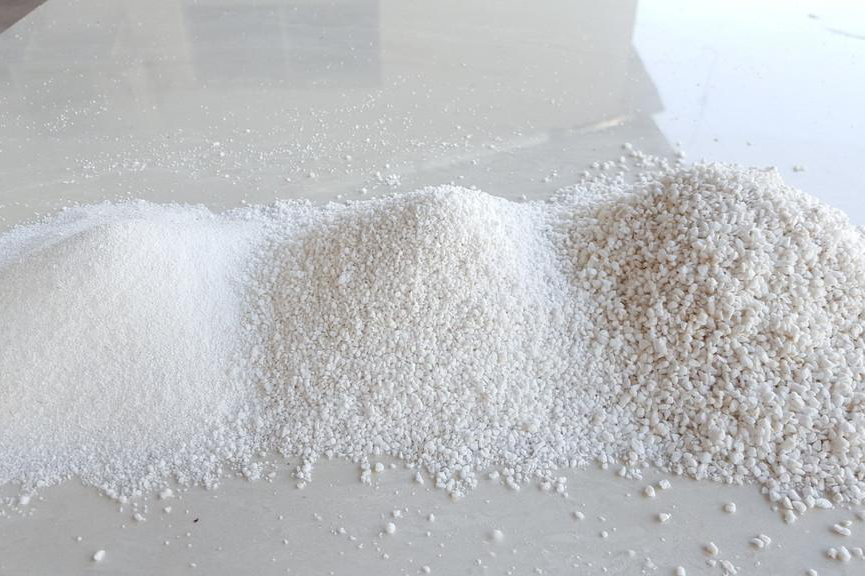

closed cell perlite is made of perlite ore with a certain particle size in a vertical electric furnace cascade heating method, and then expands uniformly from the inside to the outside after reaching a certain temperature. The surface of the expanded particles is vitrified at an instant high temperature, and the continuous vitrification is formed after cooling. The surface of the particles, and the inside maintains a complete porous, hollow structure. The unique production method determines that the product maintains the purity of the natural inorganic chemical composition of perlite. The structural feature of the product is that the surface of the particles is micro-pores and continuous vitrified luster, and the content shows a few or dozens of tiny spherical accumulations, and the color is white. The bulk density of the product is 110~350kg/cubic; the particle size is 5~1500μm.

closed cell perlite extends the application field of expanded perlite. closed cell perlite has the characteristics of high strength, low water absorption, high strength, good mixing, and easy dispersion. It is the main ingredient for the production of thermal insulation mortar, thermal insulation coatings, refractory bricks, and enamel materials. ,Widely used in wall internal and external thermal insulation mortar, refractory materials, decorative panels, thermal insulation board aggregates, metallurgy, industrial furnace electric insulation, thermal pipes and other high-end thermal insulation materials and lightweight fillers, high-fineness closed-cell perlite It can be used as filler for rubber, enamel, paint and plastic.

Technical performance of closed cell perlite

Grain size (mm) 0.1-1.5

Bulk density (Kg/m3) 100-200

Thermal conductivity (w/m.k) 0.047-0.054

Ball formation rate (%) 70-90

Closed cell rate (%) ≥95

closed cell perlite Application

Excellent light weight, strength and thermal and electrical insulation properties determine that closed cell perlite has a wide range of Application :

1.closed cell perlite can replace river sand as aggregate to configure internal and external wall thermal insulation mortar, can make high-grade thermal insulation decorative board, can be used as the main ingredient of refractory brick and enamel material; when it is used as light aggregate of thermal insulation mortar and coating and other light fillers , Sprayable and wipeable, low crushing rate in product molding processing, effectively reducing compression ratio and drying cost.

2.closed cell perlite can be used as high-end thermal insulation materials and lightweight fillers in construction, metallurgy, industrial furnaces, high and low temperature engineering thermal pipelines and other industries;

3.closed cell perlite can also be used to produce oil well cement lightening agent (oil field cement lightening agent and has the following advantages: extremely low filling density, thereby reducing the density of the product, saving costs; small specific surface area, low oil absorption, so it can be filled in large quantities; The product has a certain heat insulation performance; it can improve the impact strength of the product; it can improve the heat resistance of the product; it can reduce the heat shrinkage rate of the product)

4.Used in other materials: thermal insulation coatings; lightweight, heat-insulating and sound-insulating plastic plates; lightweight, wear-resistant, low-cost rubber conveyor belts; modified asphalt; reinforced plastic steel doors and windows, etc.; glass fiber reinforced plastic or other composite material fillers; artificial leather ; Lightweight refractory materials; refractory casting materials; thermal insulation materials; buoyancy materials, also used as materials for adjusting the density of emulsion explosives.

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Zirconia Powder Supplier – bulk Closed Cell Perlite For Thermal Insulation Mortar – Xinzheng Cheng , The product will supply to all over the world, such as: Saudi Arabia, Suriname, Mexico, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.